Advanced Engineering Polymers for Oil & Gas Exploration & Production Equipment

Advanced Engineering Polymers for Oil & Gas Exploration & Production Equipment

Symmtek products for Oil & Gas applications where developed to respond to the continuing demand for products capable of operating in extreme conditions found in harsh oil & gas well environments. These environments present many challenges for polymer products requiring: high temperature & pressure performance, chemical resistance to oil-well bore-fluids & gases, permeation resistance, mechanical strength, as well as dielectric and conductive behavior.

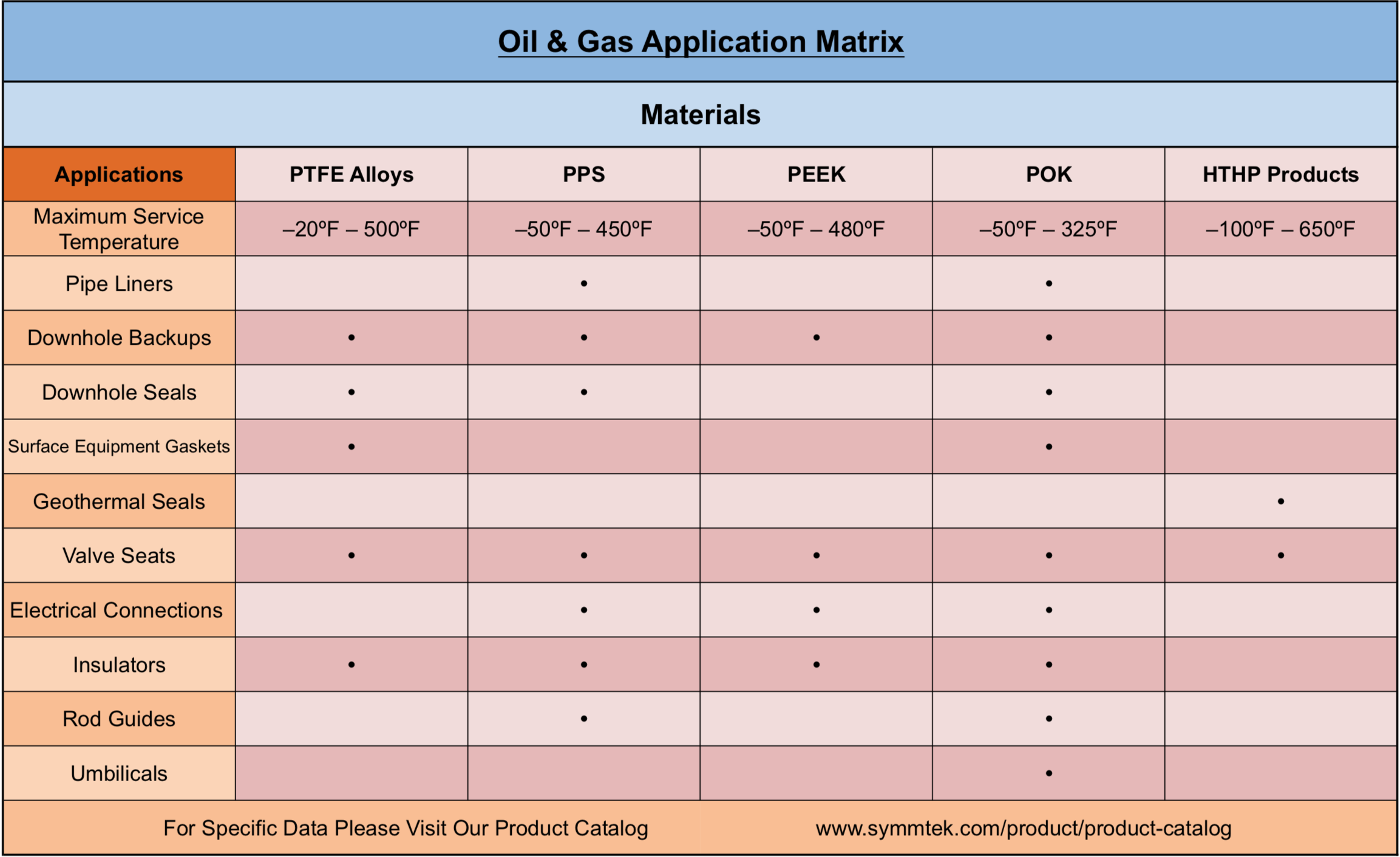

Symmtek’s advanced engineering polymers are used in several Oil & Gas downhole applications requiring extreme performance at high pressure and high temperature:

- Mechanical property retention and dimensional stability from -50C to 360C (-60F to 675F).

- Excellent long- term aging resistance

- Good flexibility and impact strength down to -90C (-130F)

- Good permeation resistance

- Resistance to gas decompression

- Ability to seal up to 10,000-20,000 psi at elevated temperature up to 360C (675F)

Extensive Portfolio of Products:

- Olefinic Polyketone, filled & unfilled

- Aromatic Polyketones, filled and unfilled

- Fluoropolymers, unfilled, filled and alloys with rigid polymers

- Imidized polymers: PAI, PI and PBI for extreme temperature, low wear and dielectric properties ate elevated temperatures

Excellent Track Record and Proven Performance Up to 675 ºF, 10,000 psi in:

- Downhole interconnecting devices for MWD

- Permanent & Retrievable Packer sealing rings and back up rings

- Valve seats with low brake away torque at elevated temperature

- Blow-Out Preventer Packing and Ram Seals for steam injection operation up to 650F, 2,200 psi

- Sliding Sleeve sealing elements

- Liner Hanger seal rings

- Steam expansion Joint seals servicing 675F, 10,000 psi wells

- SAG-D service pump wear components