ALFLON A/SM AND JE SERIES MATERIALS

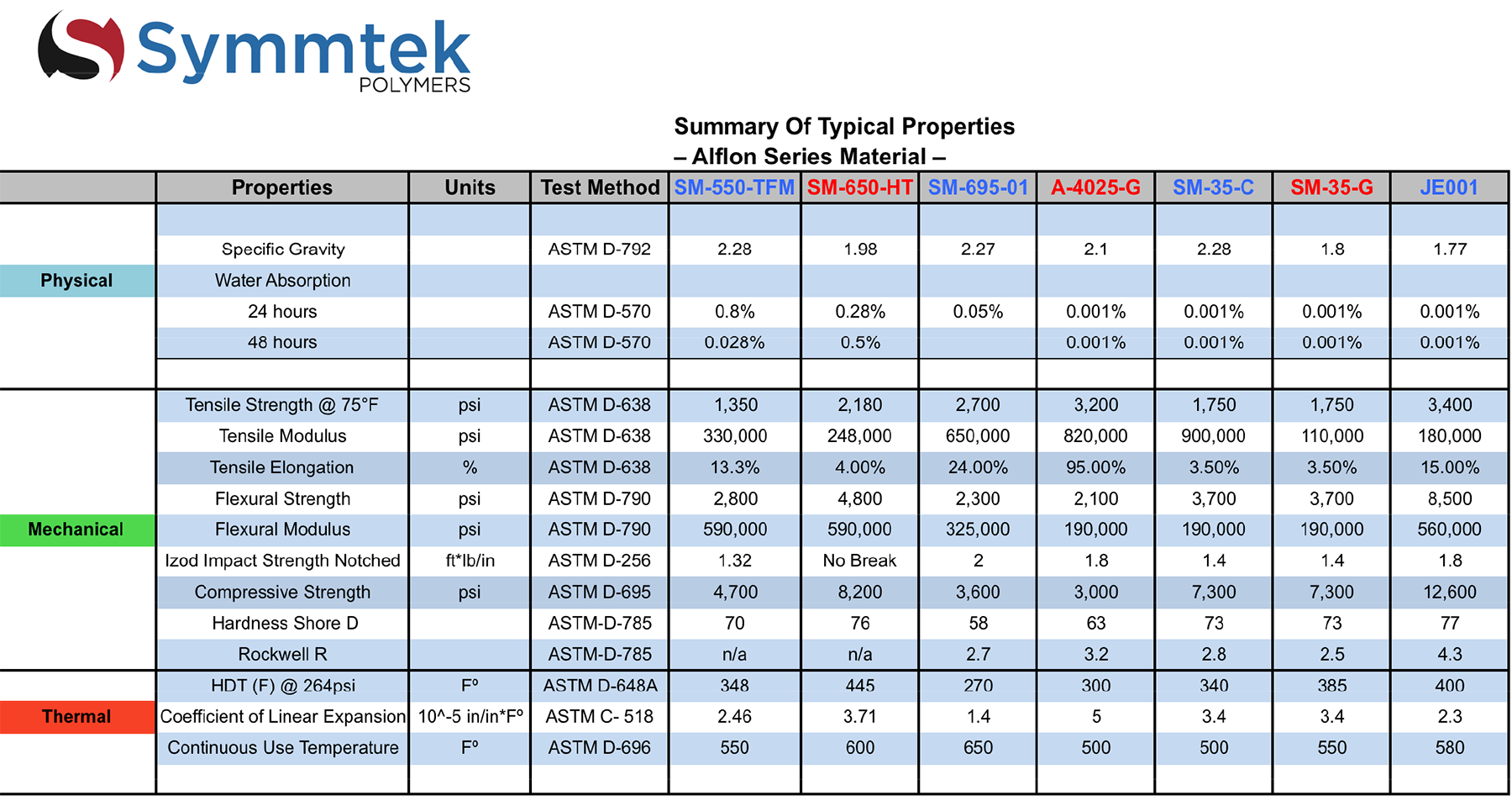

The A-Series of Alflon compounds are standard PTFE-filled products for service temperatures ranging from cryogenic to 500ºF.

The SM-Series products are PTFE fluoropolymers alloyed with Polyphenylene-Sulfide and reinforced with graphite/carbon fibers. This line was developed to offer higher compressive strength, better thermal conductivity, and higher abrasion resistance with decreased creep and thermal expansion.

The JE-Series materials are designed for ultra-performance in a fluoropolymer-based compound. These materials provide excellent compressive strength and offer temperature performance up to 500ºF.

Products

SM-550-TFM-HT: is a fluoropolymer-based compound reinforced with mica, designed for demanding applications requiring dimensional stability in a PTFE-based product, and excellent abradability for abradable seals in rotating equipment. Compression-molded parts and shapes offer superior thermal and mechanical properties making them suitable for extreme environment components requiring high-temperature, high-pressure, and creep resistance. Ideal for abradable seals for turbo- equipment.

SM-650-HT: is a perfluoropolymer-based compound reinforced with polymer and ceramic fibers. SM-650-HT is designed for extreme conditions of temperature and pressure. Compression molded parts and shapes offer superior sealing and wear performance. 650-HT has been tried and proven in steam injection, oil-field equipment seals.

SM-695-01: is a perfluoro polymer-based compound reinforced with proprietary ceramics and fibers specifically designed for extreme applications requiring high-temperature stability. Compression molded parts and shapes offer superior thermal and mechanical performance up to 675ºF and 10,000 psi. SM-695-01 is suitable for SAGD service components requiring high-temperature, high-pressure, and creep resistance in steam and hydrocarbon service.

A–4025–G: carbon/graphite filled PTFE with improved thermal and electrical conductivity. Very low coefficient of friction, excellent wear resistance in dry and wet environments while maintaining PTFE’s excellent resistance to corrosion media. A- 4025-G is the best PTFE compound for bearings, flow meter gears, compressor packings, and oil-tool sealing elements.

SM-35-C/SM-35-G: PPS filled PTFE reinforced with carbon fibers and proprietary fillers for improved mechanical properties. These compounds extend the application of fluoropolymers to areas with higher pressure and temperature than previously provided by standard PTFE-filled products. These materials are designed for seals of all sorts, compressor component wear pads, back-up rings, and applications where PTFE tends to cold flow or extrudes under heat and pressure; recommended for temperature service up to 475ºF in the presence of extreme loads up to 10,000 psi.

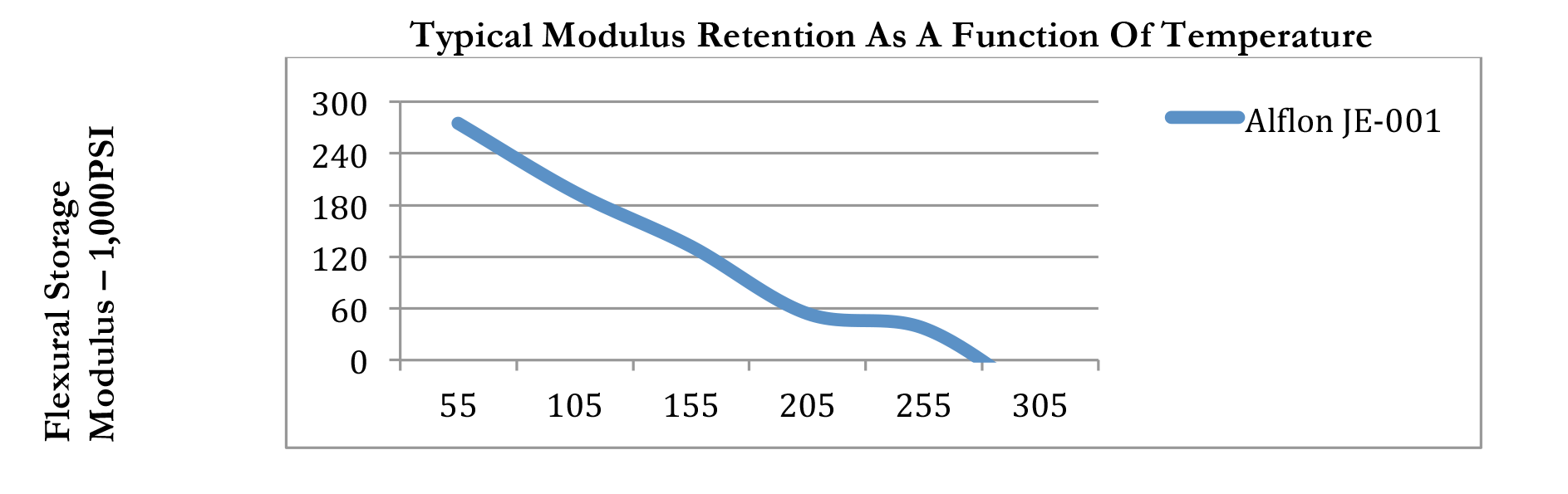

JE-001: PTFE alloyed with Polyetheretherketone polymers and reinforced with proprietary fibers. This alloy is designed for ultimate performance in extreme conditions of temperature and pressures, offering maximum performance under compression for specialty seals, oil-tool sealing elements, ball valve seats, compressor wear rings, and medium pressure bearings. JE-001 offers the chemical resistance of PTFE, elastomeric type compliance, and the thermal resistance of PEEK.

Have a question on Material Selection or Need More Info on Machining?

Call Us Today!

To the best of our knowledge the information contained herein is accurate. However, neither Symmteck Polymers LLC, nor its affiliates assumes any liability whatsoever for the accuracy or completeness of the information contained herein. Final determination of suitability and whether there is any infringement of patents is the sole responsibility of the user.

Symmtek Polymers LLC

123 Gantry Lane

Calera, OK 74730

(303) 670-8820