PEKTRAN PR SERIES MATERIALS

PEKTRAN PR Series Materials are a class of high-temperature, semi-crystalline aromatic polymer compounds based on Polyaryletheretherketone resin.

The wholly aromatic structure of the PEKTRAN compounds is responsible for the high-temperature performance and outstanding mechanical and electrical properties in chemically hostile environments. The diversity of end-use applications has led to the development of several grades, each formulated and molded to maximize specific properties.

Product

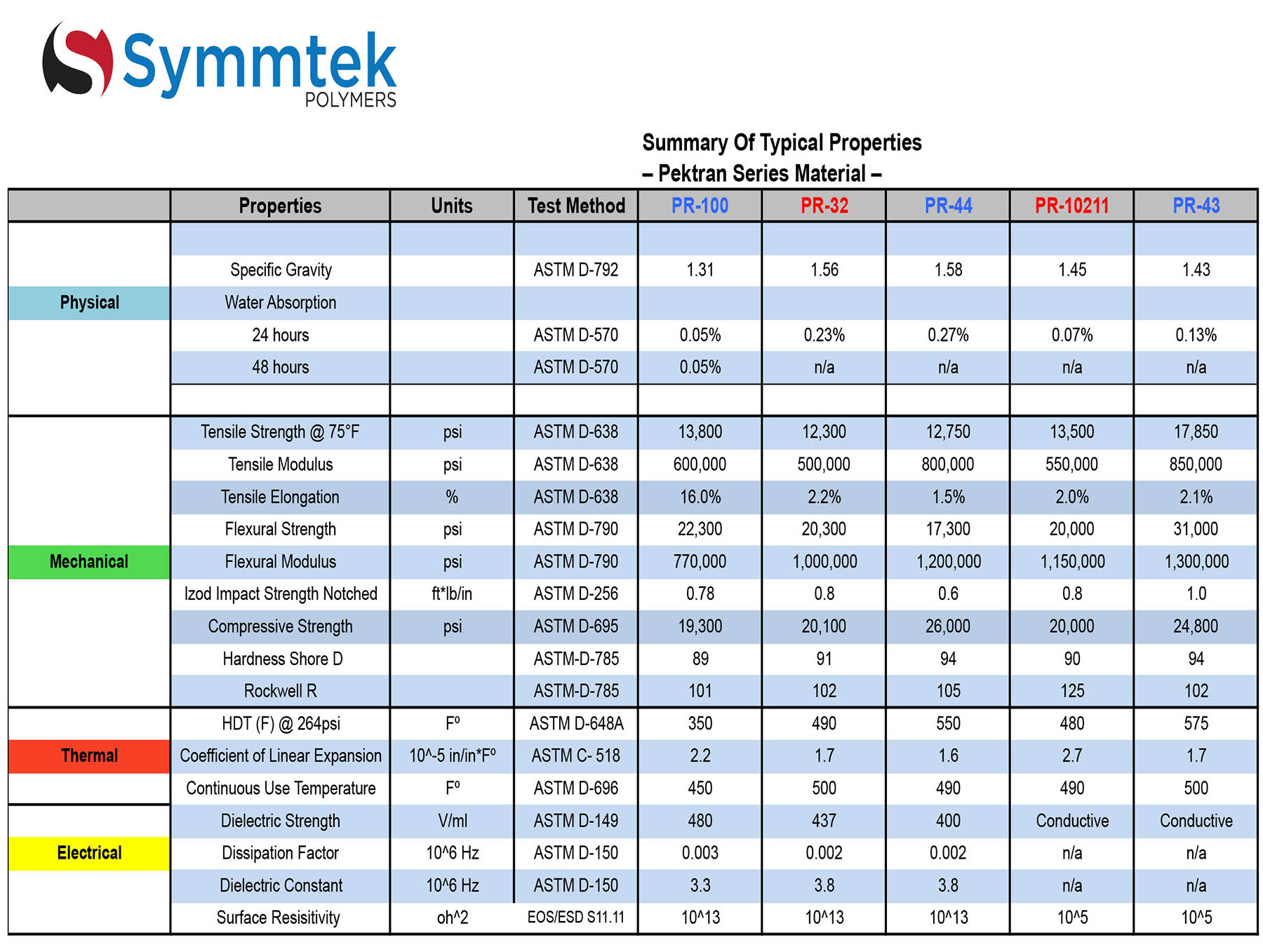

PR-100: Unreinforced grade molded from 100% virgin resin. Unfilled, PEKTRAN PR provides a well-balanced combination of rigidity, strength, and excellent ductility and impact resistance. PEEK PR-100 is ideal for high resiliency seals, back-up rings, valve seats for harsh and nuclear environments, packing distillation columns, high-temperature, and high-pressure electrical insulators.

PR-32: 30%glass fiber reinforced version. By adding glass fibers the material yields a higher tensile and flexural modulus than the unreinforced grade with good retention of properties up to 525º F in a variety of media. PR-32 is excellent for electrical insulators at elevated temperatures and superior material for anti-extrusion rings for oil tools and hydraulic devices. It is also currently being utilized for cable and hose connectors, heat exchanger parts, gears and transmission devices, and pump and compressor components.

PR-44: Specialty glass fiber-filled grade. Designed for maximum property retention at elevated temperatures without a premium. This product is recommended for process engineering applications such as seals for valves, pumps, compressors, roller clutches, friction bearings, impellers, extrusion sealing devices, and high-temperature insulation.

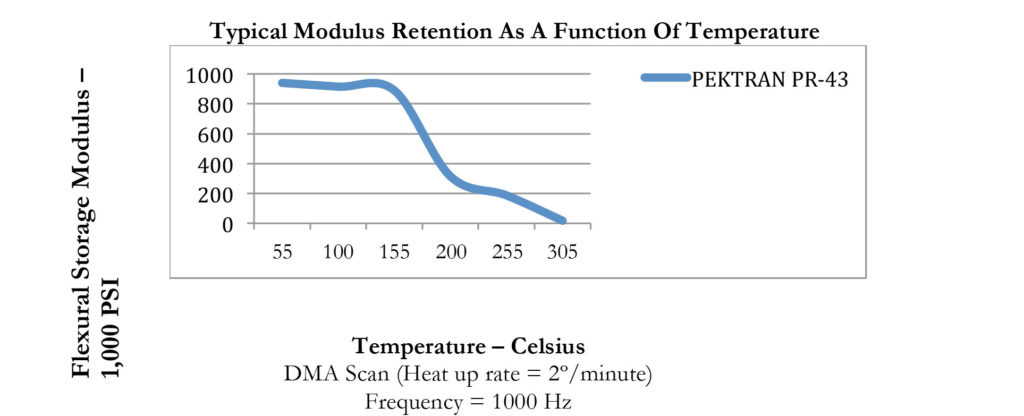

PR-43: Compression-molded 30%, carbon-fiber filled PEEK polymer. Reinforced for maximum improvement (versus glass) in tensile, flexural, and compressive strengths. Flexural modulus is as high as seven times the base resin. As an excellent metal replacement, typical uses are: compressor and pump mechanical devices such as casings, rotors, vanes, valve plates, and high-precision gears with low expansion rates. Other applications include high compression packings and valve seats for critical services such as deep oil wells, petrochemical production, and nuclear plants.

PR-10211: Compression-molded graphite, PTFE lubricated, carbon-fiber-reinforced PEEK polymer. This grade provides low- friction, low wear at elevated temperatures, excellent tribological characteristics at medium load, and speed against metals. Applications: bearings, thrust washers, wear pads, pistons, piston rings, and mechanical seals.

Have a question on Material Selection or Need More Info on Machining?

Call Us Today!

Corrosion resistance charts will be sent upon request. If your application demands other fillers or reinforcements different than those listed as standard, Symmtek can provide custom-molded compounds to meet your specific needs.

To the best of our knowledge the information contained herein is accurate. However, neither Symmteck Polymers LLC, nor its affiliates assumes any liability whatsoever for the accuracy or completeness of the information contained herein. Final determination of suitability and whether there is any infringement of patents is the sole responsibility of the user.

Symmtek Polymers LLC

123 Gantry Lane

Calera, OK 74730

(303) 670-8820